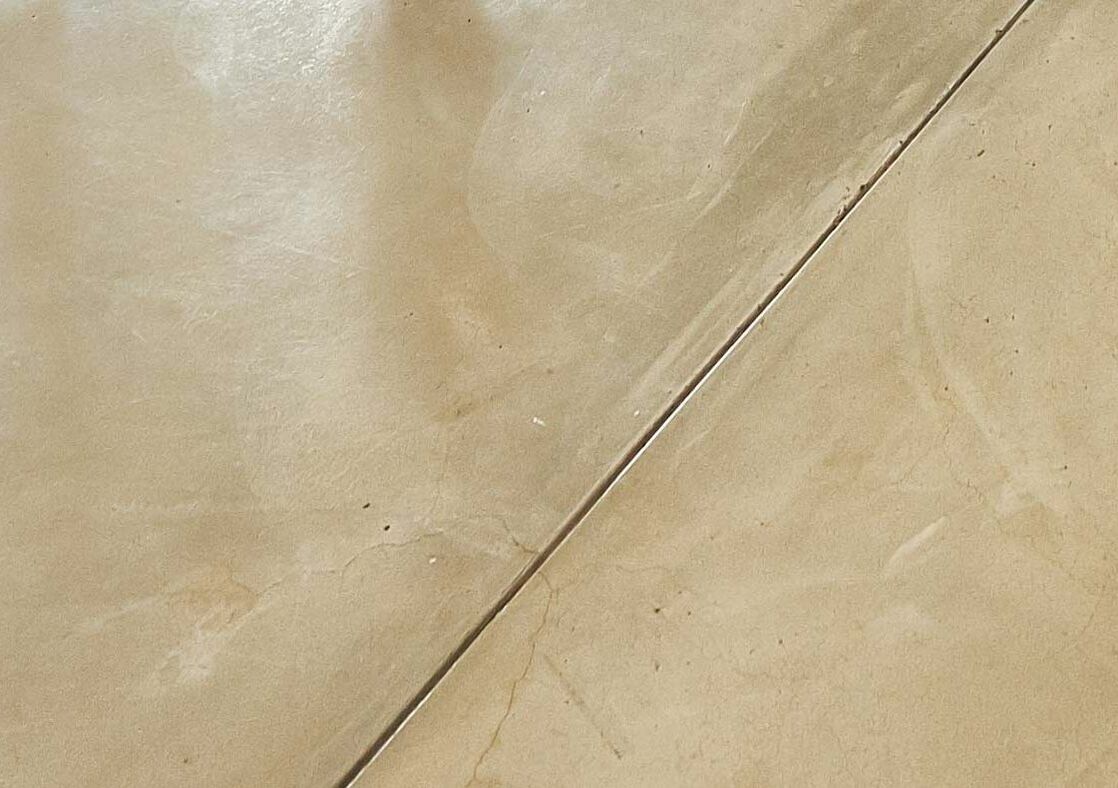

This is the most common question asked when it comes to decorative cement finishes – will it crack? And the simple answer is yes - hairline cracking is normal. But there is a much more complex process behind why they crack, and understanding these factors and taking certain measures in the planning and execution phases that can reduce the amount of cracking significantly.

By nature, cement is not flexible. So movement and temperatures causing expansion and contraction may cause fine hairline cracks. This is part of the natural element and adds to the look and feel. It must also be remembered that decorative cement coatings that are usually around 1.5 – 2mm in thickness are affected mostly by the state of the substrate beneath, than itself being prone to cracking.

There are many factors that can influence the formation of cracks, and here is a summary of the most common:

There are many factors that can influence the formation of cracks, and here is a summary of the most common:

|

Incorrect amount of water added to the cement mix

Contractors usually add too much water to make working with the cement mix easier. However this causes excessive evaporation of the excess water, leading to excessive shrinkage, the result of which is cracking. This also affects the overall strength of the concrete. Incorrect cement strength in the mix

Cement is available in a range of strengths, and the correct strength for the specific job is very important. It is also important to match the strength of the substrate concrete to the strength of the decorative cement coating for best results. |

|

Rapid drying

The process whereby concrete sets or cures requires water. This chemical reaction, called hydration, is a long process and takes days to weeks. By adequately curing the concrete (usually by wetting daily) you can assist this process to take place at the correct rate and not to dry out too quickly which would lead to excessive evaporation, resulting in cracking. Rapid drying is also more of a problem for external applications where the concrete is exposed to sunlight, wind and rain. This can be controlled by protecting the site with shade cloths and barriers; a planning step that can make all the difference between a successful and unsuccessful project. |

|

Incorrect expansion and control joints

Expansion joints are placed in order for the substrate concrete to have enough space to move during the hydration or curing phase. Placement of the expansion joints is vitally important to minimise the visibility of structural movement cracking – usually on corners of walls, in doorways, etc. Large areas will require expansion joints at certain intervals to allow the correct expansion & contraction of the concrete as it cures. In order for the contractor to be able to complete each section timeously & therefore correctly – trying to do panels that are too big for the contracting team to handle can lead to one or a number of the factors mentioned above, leading to cracking. In essence expansion & control joints are “planned cracks” – making sure that if & when a structural crack does occur, it is where you’ve planned it to be, & in a straight line, rather than randomly on its own path which may become unsightly. It is also important to cut these joints deep enough & soon enough; they can later be filled with an expandable material to lessen the site of them, & prevent dirt & debris getting stuck in them. |

|

Weather

As mentioned already direct sunlight, wind and rain can all affect the hydration process, but so can temperature. Excessive heat (both dry and humid heat) will play a role in the hydration process, as well as freezing conditions. For cement freezing conditions start at 5ºC, not 0ºC as one would presume. At 5ºC and below water begins to expand before it actually turns to the solid state of ice. This expansion creates bigger voids in the cement as it cures, and once this ice melts and evaporates, leaves bigger voids than the cement can handle (also breaking the cement bonds), resulting in cracking. Yes, hairline cracking in cement-based coatings are normal, but hire a trained & experienced contractor and bigger cracks than that are unlikely to appear. When in doubt, contact us for applicator details or technical support.

|