WHAT IS COLOUR HARDENER?

A granolithic concrete material that is floated into fresh screed or concrete which colours, strengthens and creates durable surfaces for the concrete floors. It is a special blend of cement incorporating very hard-wearing aggregates, light fast pigments and additives which set rock-hard.

A granolithic concrete material that is floated into fresh screed or concrete which colours, strengthens and creates durable surfaces for the concrete floors. It is a special blend of cement incorporating very hard-wearing aggregates, light fast pigments and additives which set rock-hard.

PRODUCT INFO

-

DETAILS

-

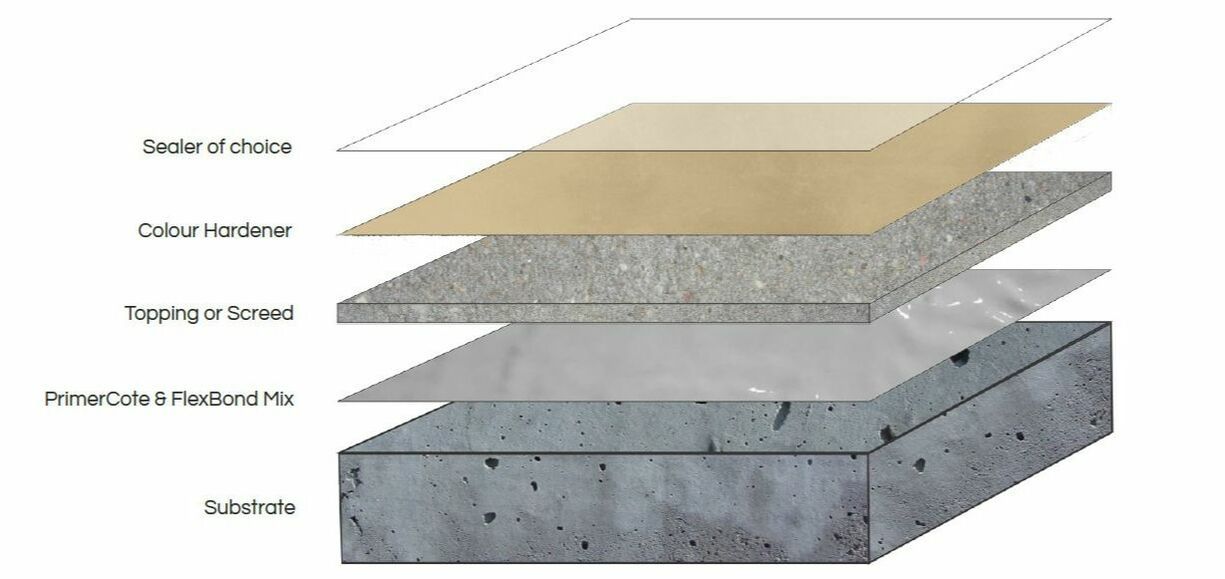

SYSTEM

-

USES

-

FAQ

-

DOWNLOADS

<

>

Benefits

- Can be used for interior & exterior floors

- Suitable for domestic or commercial projects

- Colours concrete to a depth of 2 - 3mm - No risk of colour being rubbed off or abraded

- Extremely durable (but is dependent on screed mix and curing)

- Can be used in conjunction with SuperScreed (10 - 20mm) where there are height restrictions

- Can be imprinted with patterns to create stamped concrete

Specifications

Suitable Surfaces |

Interior & exterior concrete or screed base |

Finish |

Steel trowel to a smooth finish Textured, stamped or rolled to obtain different tiled or paved effects |

Thickness |

Depending on screed design - colour penetrates 2 - 3mm into screed |

Application |

Sprinkle-on & trowelled |

Packaging |

20kg bags |

Coverage |

Approximately 5m² per 20kg bag |

Curing |

Leave to air cure for 1 day after completion Damp down with water twice daily for 7 days Allow to dry for a minimum of 14 days before sealing |

Colour/s |

Available in 15 colours |

What do you need?

|

Tools & Consumables

|

Products

|

The System

FLOOR PANELS |

IMPRINTED / STAMPED CONCRETE

|

Please consult with your area representative for further technical and application details.

Q: Can my builder do the Colour Hardener application?

A: If your builder has experience working with Cemcrete products and you feel confident in using them to do the application, then yes. Your builder can also attend our demo days hosted at our Academy in Johannesburg. For more info on these demonstration days, click here. Cemcrete can also provide you with independent contractor details in you area. Click here and complete your project details in order for us to assist you with the best contractor for your needs. The independent contractors will provide you with a quote including the product and labour.

Q: What type of screed or topping mix should be used with Colour Hardener?

A: For the screed or topping mix please follow the guidelines as set out by the Concrete Institute in their sand, cement, screed brochure.

Q: Do you have to seal a Colour Hardener floor?

A: Yes. Cement by nature is porous and applying a sealer ensures that your cement floor is protected from any spills or normal wear and tear.

Q: Can I power float a floor after Colour Hardener application?

A: Yes a Colour Hardener floor of a large area can be power floated. Please contact our technical team for more information on the process or download the datasheet here.

Q: How long after the Colour Hardener application can you walk on the floor?

A: After 24 hours light foot traffic is allowed for curing and sealing purposes only.

Q: Will my Colour Hardener floor crack and what measures can be taken to minimise the chances of it happening?

A: Hairline cracking is normal, by nature cement is not flexible, so movement and temperature variances causing expansion and contraction and shrinkage may cause fine hairline cracks. This is part of the natural element of a cement finish and adds to the unique look and feel. However the correct preparation and application processes are vital to avoid bigger cracks from appearing. Also adding expansion joints, dividing your cement floor into big blocks, can help to allow for movement and could prevent larger cracks from appearing.

A: If your builder has experience working with Cemcrete products and you feel confident in using them to do the application, then yes. Your builder can also attend our demo days hosted at our Academy in Johannesburg. For more info on these demonstration days, click here. Cemcrete can also provide you with independent contractor details in you area. Click here and complete your project details in order for us to assist you with the best contractor for your needs. The independent contractors will provide you with a quote including the product and labour.

Q: What type of screed or topping mix should be used with Colour Hardener?

A: For the screed or topping mix please follow the guidelines as set out by the Concrete Institute in their sand, cement, screed brochure.

Q: Do you have to seal a Colour Hardener floor?

A: Yes. Cement by nature is porous and applying a sealer ensures that your cement floor is protected from any spills or normal wear and tear.

Q: Can I power float a floor after Colour Hardener application?

A: Yes a Colour Hardener floor of a large area can be power floated. Please contact our technical team for more information on the process or download the datasheet here.

Q: How long after the Colour Hardener application can you walk on the floor?

A: After 24 hours light foot traffic is allowed for curing and sealing purposes only.

Q: Will my Colour Hardener floor crack and what measures can be taken to minimise the chances of it happening?

A: Hairline cracking is normal, by nature cement is not flexible, so movement and temperature variances causing expansion and contraction and shrinkage may cause fine hairline cracks. This is part of the natural element of a cement finish and adds to the unique look and feel. However the correct preparation and application processes are vital to avoid bigger cracks from appearing. Also adding expansion joints, dividing your cement floor into big blocks, can help to allow for movement and could prevent larger cracks from appearing.