WHAT IS CRETECOTE?

A pigmented, thin film cement-based coating which is versatile and durable. It is a two coat system which produces a 1.6mm smooth decorative finish suitable for application onto wood or steel floated concrete floor slabs and screeds, ceilings and plastered or previously painted walls. For interior and exterior walls, and interior floors only.

A pigmented, thin film cement-based coating which is versatile and durable. It is a two coat system which produces a 1.6mm smooth decorative finish suitable for application onto wood or steel floated concrete floor slabs and screeds, ceilings and plastered or previously painted walls. For interior and exterior walls, and interior floors only.

PRODUCT INFO

-

DETAILS

-

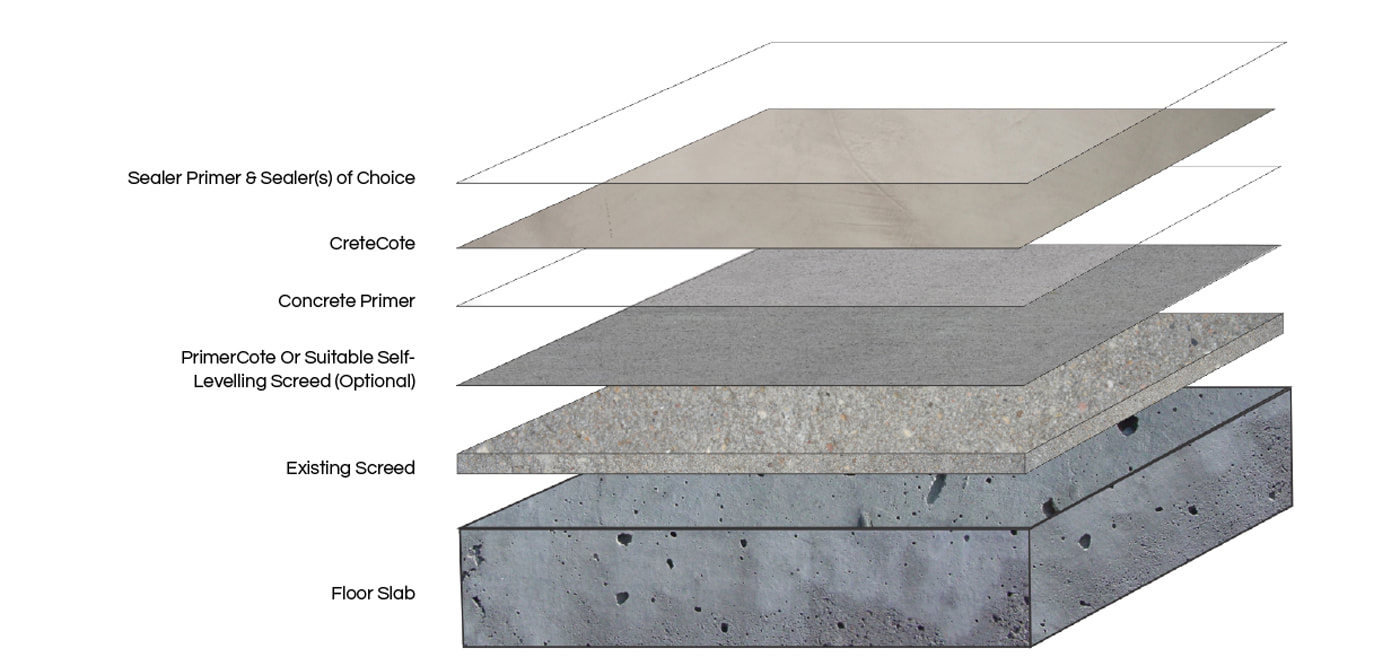

SYSTEM

-

USES

-

DOWNLOADS

-

VIDEO

-

FAQ

<

>

Benefits

- Thin skim-on coating perfect for renovations

- Application with a steel trowel

- Interesting colour variation

- Versatile application - can be used to coat walls, floors, counters & vanities

- Reaches a compressive strength of 35MPa after 28 days (this is solely dependent on the substrate)

Specifications

Suitable Surfaces |

Wood or steel floated concrete floor slabs or screeds and counter / vanities - Interior surfaces only Walls - Interior and exterior surfaces New surfaces should be allowed to cure for at least 28 days Tiles with the necessary preparation steps to ensure even suction & adhesion |

Finish |

Smooth |

Thickness |

Minimum 1.6mm over 2 coats (maximum 0.8mm per coat – two coat application) |

Application |

Sponge & trowel-on |

Packaging |

15kg twinpack container OR 10kg powder paper bag and 5L liquid container |

Coverage |

8 - 10m² per 15kg twinpack / 10kg & 5L combined mix |

Curing |

The completed work should be allowed to air cure for 48 hours before sealing The moisture in the floor must be less than 5% prior to sealing |

Colour/s |

Available in 15 colours |

What do you need?

|

Tools & Consumables

|

Product

|

The System

Please consult with your area representative for further technical and application details.

Q: Can my builder do the CreteCote application?

A: If your builder has experience working with Cemcrete products and you feel confident in using them to do the application, then yes. Your builder can also attend our demo days hosted at our Academy in Johannesburg. For more info on these demonstration days, click here. Cemcrete can also provide you with independent contractor details in you area. Click here to complete your project details in order for us to assist you with the best contractor for your needs. The independent contractors will provide you with a quote including the product and labour.

Q: Can I use CreteCote as a wall finish?

A: No. For a similar look use Cemcrete’s CemCote Skimmed as your wall finish. However, CreteCote can used to coat a built-in vanity.

Q: Can CreteCote be applied over tiles?

A: Yes it can be applied over tiles as long as the necessary preparation steps are followed to ensure adhesion to the tiles. Any glazed tiles need to be sanded or ground to remove the glazed surface. Tiles such as slasto and clay should not be coated due to their friable and flaky nature. The first and best option is always to remove the tiles.

NOTE: If the tiles were to come loose it will damage the CreteCote.

Q: How slippery is a CreteCote floor?

A: The finish in terms of slipperiness is very similar to a porcelain tile. A slip-resistant additive, which consist of fine aggregate, can be added to your final coat of sealer. This will insure your CreteCote floor has bit more grip.

Q: How long after the CreteCote application can you walk on the floor?

A: After 24 hours light foot traffic is allowed for curing and sealing purposes only.

Q: Can I use underfloor heating with a CreteCote floor?

A: No unfortunately not, however, underfloor heating can be used with Colour Hardener.

Q: Will my CreteCote floor crack and what measures can be taken to minimise the chances of it happening?

A: Hairline cracking is normal, by nature cement is not flexible, so movement and temperatures causing expansion and contraction may cause fine hairline cracks. Proper application processes are vital to avoid bigger cracks from appearing.

A: If your builder has experience working with Cemcrete products and you feel confident in using them to do the application, then yes. Your builder can also attend our demo days hosted at our Academy in Johannesburg. For more info on these demonstration days, click here. Cemcrete can also provide you with independent contractor details in you area. Click here to complete your project details in order for us to assist you with the best contractor for your needs. The independent contractors will provide you with a quote including the product and labour.

Q: Can I use CreteCote as a wall finish?

A: No. For a similar look use Cemcrete’s CemCote Skimmed as your wall finish. However, CreteCote can used to coat a built-in vanity.

Q: Can CreteCote be applied over tiles?

A: Yes it can be applied over tiles as long as the necessary preparation steps are followed to ensure adhesion to the tiles. Any glazed tiles need to be sanded or ground to remove the glazed surface. Tiles such as slasto and clay should not be coated due to their friable and flaky nature. The first and best option is always to remove the tiles.

NOTE: If the tiles were to come loose it will damage the CreteCote.

Q: How slippery is a CreteCote floor?

A: The finish in terms of slipperiness is very similar to a porcelain tile. A slip-resistant additive, which consist of fine aggregate, can be added to your final coat of sealer. This will insure your CreteCote floor has bit more grip.

Q: How long after the CreteCote application can you walk on the floor?

A: After 24 hours light foot traffic is allowed for curing and sealing purposes only.

Q: Can I use underfloor heating with a CreteCote floor?

A: No unfortunately not, however, underfloor heating can be used with Colour Hardener.

Q: Will my CreteCote floor crack and what measures can be taken to minimise the chances of it happening?

A: Hairline cracking is normal, by nature cement is not flexible, so movement and temperatures causing expansion and contraction may cause fine hairline cracks. Proper application processes are vital to avoid bigger cracks from appearing.